- Home

- Bandsaws

- Circular blade saws

- Accessoires

- Selection tool

- Service

- Contact

- News

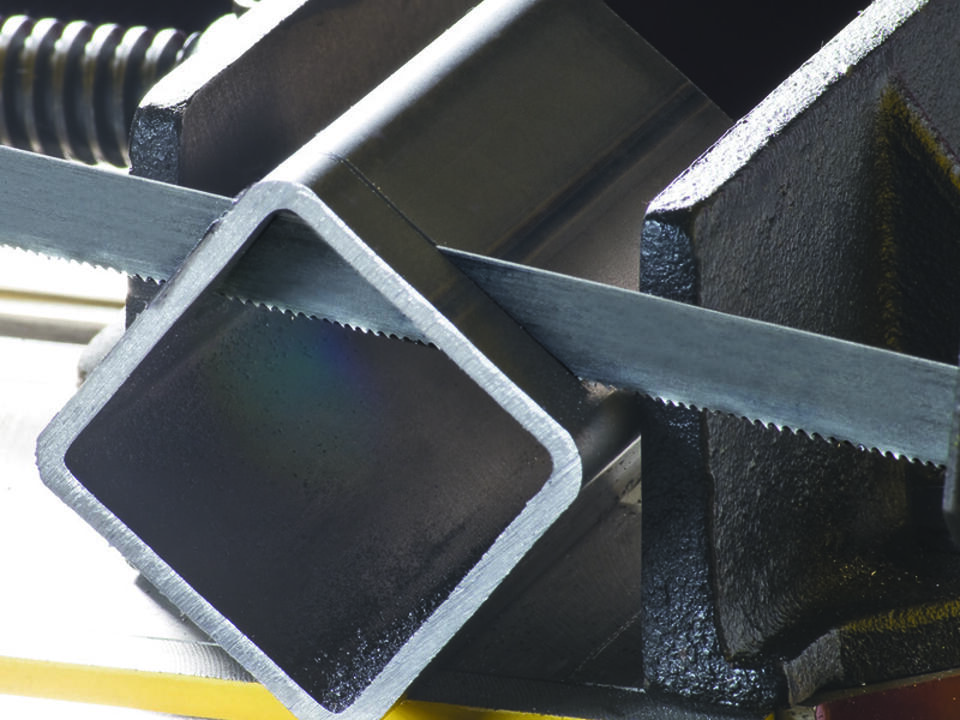

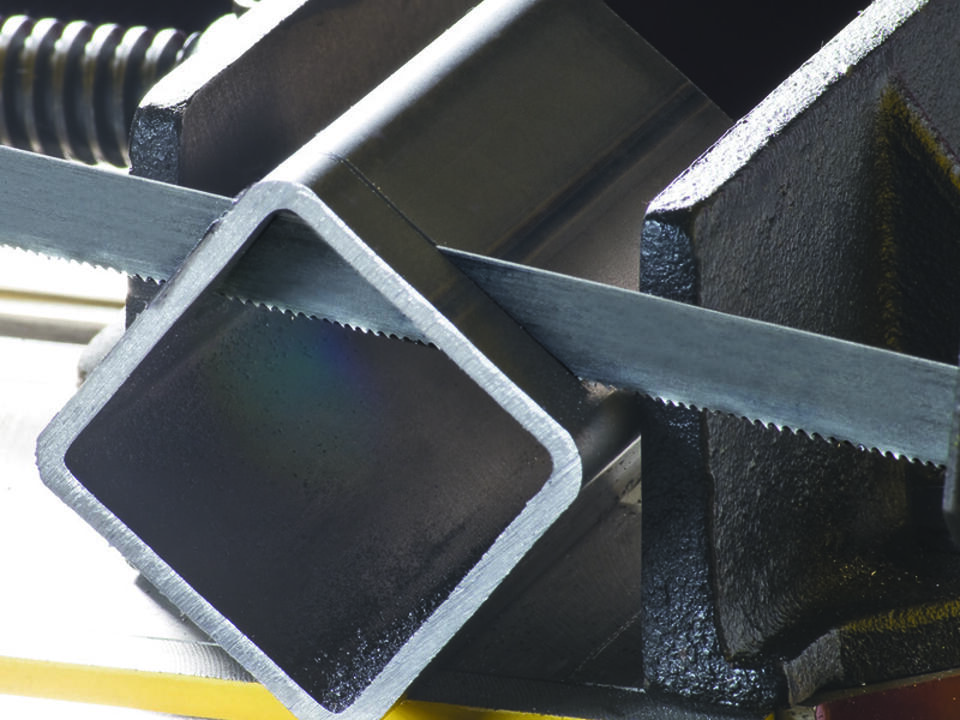

Metal bandsaws are an indispensable tool in the metalworking industry. Whether you're cutting steel, aluminum, or stainless steel, choosing the right metal bandsaw makes a world of difference. In this blog post, you’ll discover why the bimetal M42 bandsaw blade is a favorite among professionals, its advantages, and how to get the most out of your saw blade.

A bimetal M42 bandsaw blade is made from two types of metal. The blade’s back is composed of flexible spring steel, while the teeth are made of high-speed steel (HSS) with 8% cobalt. This makes the teeth extremely durable and resistant to high temperatures, making it ideal for cutting hard metals such as stainless steel, tool steel, and alloys.

Thanks to the combination of these metals, the blade offers a perfect balance between flexibility and wear resistance. This means less risk of cracking or breaking, even under intensive use. That’s why a bimetal M42 bandsaw blade is a cost-effective choice for metalworkers looking for longevity and consistent performance.

When selecting a bimetal M42 bandsaw blade, the teeth per inch (TPI) is a crucial factor. A low TPI (2-6) is ideal for thicker metals, while a high TPI (10-24) is best for thinner materials. The right TPI ensures better cutting quality and prevents excessive wear on the blade.

These bandsaw blades are ideal for various applications, including:

A bimetal M42 bandsaw blade is an essential tool for any metalworker seeking reliability, durability, and versatility. Investing in a high-quality blade like the M42 not only enhances the quality of your work but also saves money in the long run.

Are you looking for the perfect bandsaw blade for your metalworking projects? Check out our range of high-quality bimetal M42 bandsaw blades and experience the difference yourself!

Terms and Conditions | Privacy Policy | © Copyright 2022 Custombandsaws.com